How Damascus Steel Is Forged

1. Selecting the Right Steel

The process begins with choosing two or more types of steel—typically a high-carbon steel for hardness and a low-carbon steel for flexibility. These are layered to combine the best properties of each material.

2. Stacking and Preparing the Billet

The steel layers are cut into strips and stacked alternately. This stack, known as a billet, is welded together to ensure the layers do not separate during forging.

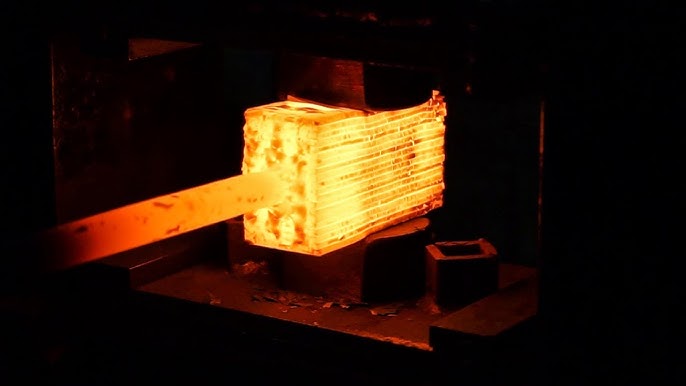

3. Heating the Billet

The billet is heated to extreme temperatures in a forge, typically around 2,000°F (1,093°C). At this temperature, the steel becomes malleable and ready for manipulation.

4. Forge Welding

Using a hammer or a power press, the blacksmith applies pressure to weld the layers together. The billet is folded and hammered repeatedly, increasing the number of layers and creating the intricate patterns characteristic of Damascus steel.

5. Pattern Creation

The hallmark of Damascus steel lies in its unique designs. Blacksmiths use techniques such as twisting, cutting, or grinding the billet to manipulate the layers and create patterns like raindrops, waves, or ladders.

6. Shaping and Refining

Once the desired pattern is achieved, the steel is shaped into the final form, whether it’s a blade, a tool, or decorative art. The edges are sharpened, and the surface is polished to bring out the patterns.

7. Etching the Surface

The final step involves etching the steel in an acid solution, which reacts differently with the various layers of steel, enhancing the contrast of the patterns and revealing the iconic Damascus design.

Why Damascus Steel Stands Out

-

Aesthetic Beauty: The intricate patterns make each piece of Damascus steel unique, a combination of function and art.

-

Strength and Durability: Damascus steel blades are known for their sharpness, edge retention, and resistance to shattering.

-

Historical Legacy: Owning a piece of Damascus steel connects you to centuries of blacksmithing tradition and ingenuity.

Modern Uses of Damascus Steel

While it was historically used in weaponry, modern Damascus steel is a favorite for luxury hunting knives, chef’s knives, and custom tools. Its timeless appeal ensures that it remains a symbol of craftsmanship and elegance.

Conclusion

Forging Damascus steel is a labor-intensive process that requires skill, patience, and creativity. Each piece tells a story of tradition and mastery, embodying the spirit of ancient craftsmanship. Whether you admire it for its beauty or value it for its performance, Damascus steel is truly a marvel of human ingenuity.

Explore the finest handmade Damascus steel knives and tools at HuntForge, where tradition meets modern excellence.

Wow amazing blog layout How long have you been blogging for you made blogging look easy The overall look of your web site is magnificent as well as the content